Boaz David, founder and CEO of Human B, a consultancy business for the fashion industry, says that by enabling brands to shorten the time to market, 3D technology can give them “more agility and flexibility to address current market needs, as well as reducing their inventory, both of which will impact their cash flow – the biggest challenge for brands.”

He adds that 3D solutions can also have a big impact on sustainability and waste reduction, with fewer samples meaning less material waste.

“3D solutions can also have a big impact on sustainability and reduction of waste, with fewer samples meaning less material waste.”

The extent of such benefits are underlined in a customer survey from EFI Optitex, which found that one luxury goods company had been spending close to US$30m on sampling alone – but by going digital was able to reduce the number of physical samples by 10%, saving millions of dollars.

“Other brands were able to reduce the number of physical samples from 5 to 1.5, with an average of 10-15% reduction in overall sample production costs,” says Amit Ben-Sheffer, head of product at EFI Optitex.

Jason Wang, chief operating officer at Alvanon, says “the adoption of 3D technology is certainly picking up...and we are seeing more and more brands implement or at least get educated on the subject.” However, he adds: “The reality is that it will take more time for most companies to effectively use 3D design in product development.”

The Alvanon Body Platform (ABP) is a database of over 6,000 virtual bodies

Speedier time to market

Ron Watson, VP product at Centric Software, says 3D technology empowers brands and manufacturers to revolutionise their product development processes, eliminating endless rework of designs and prototyping to make product development decisions much faster and get more innovative products to market, sooner.

“Like with any new technology implementation, establishing best practices is key for companies that are looking to gain speed with 3D technology,” he says.

“Like with any new technology implementation, establishing best practices is key for companies that are looking to gain speed with 3D technology” - Ron Watson, Centric Software

Watson adds that it is also essential for companies to implement the technology across all relevant parts of the business and ensure they are all connected on a “single source of truth.” He explains: “Avoid bottlenecks by integrating the 3D design tool with your PLM system, enabling cross functional teams to collaborate, view 3D designs and samples, and share them across the supply chain for faster and more accurate product development.”

Shared results

Dr Simeon Gill, senior lecturer in fashion technology at the UK’s University of Manchester, stresses that with 3D fit solutions, for instance, companies should ensure that all people involved in design and product development can see the results.

He notes that one company he visited was creating reports with data generated from scanning technology shared with all the teams across the company – but the scans themselves were not being shared. “So, the facility for people to understand other than numerically what their population variance is, was incredibly limited.”

“Once you’ve computerised something you can push it out and get greater access, which is a real benefit. But the company has to be prepared to do that and draw everyone on board with it.”

“End-to-end solutions flow from one to the next so each process adds value and produces a digital asset.” - Savannah Crawford, Tukatech

Savannah Crawford, chief collaborator at fashion technology company Tukatech, says another key challenge to overcome is making disparate technologies work together to make significant gains in speeding up the process from design sketch to style approval and beyond.

She says apparel companies often adopt 3D design without accounting for fit or how the garment will be made upon approval, for instance. “They have a beautiful 3D garment on screen, but they need a separate CAD (computer aided design) system to prepare for production.”

Tukatech aims to help brands resolve this problem with its TUKAcad pattern-making and grading solution, which imports 2D patterns directly to TUKA3D, its virtual sample making tool. Once the 3D sample has been approved, the manufacturer can also use TUKAcad for remaining pre-production work, and costing or production markers. “Tukatech’s end-to-end solutions flow from one to the next so each process adds value and produces a digital asset,” says Crawford.

“Workflow of repeatability”

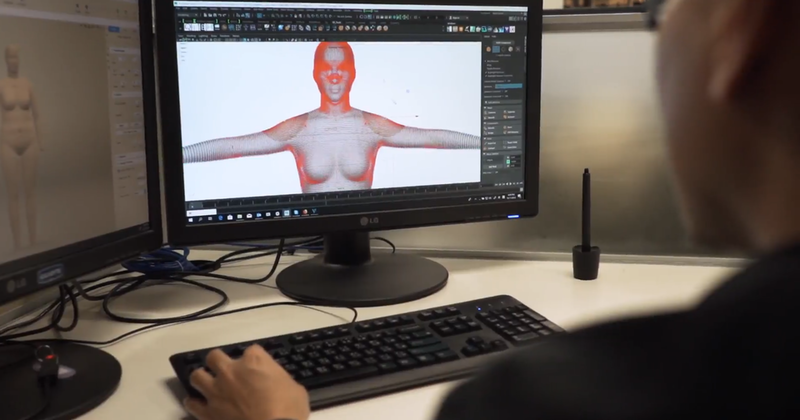

Another option is US-based Gerber Technology’s 2D-to-3D CAD solution AccuMark 3D, which Ketty Pillet, vice president of marketing, says “allows clients to establish a workflow of repeatability, consistent quality, and consistent fit.”

She adds that when the 3D solution is paired with a powerful nesting algorithm (laying out cutting patterns to minimise raw material waste), such as Gerber’s AccuNest, designers can estimate fabric consumption, resulting in 15-20% fabric savings.

Pillet stresses that even small companies and startups should adopt 3D. “Imagine being able to build your virtual clothing line, put it out on social media, see how many likes you get, and then go out and buy fabric for the styles with the highest likes only. Fabric inventory unused could put a small company out of business.”

Headline image: Gerber Technology's AccuMark incorporates 3D simulation

BACK TO TOP