The business benefits of 3D virtual design, fit and prototyping

Amid growing pressures for shorter development cycles, faster time to market and reduced waste, clothing brands and retailers are increasingly looking to leverage the benefits of 3D virtual design and prototyping tools to deliver quick wins across areas such as fit, design, sampling and workflow. By Jonathan Dyson

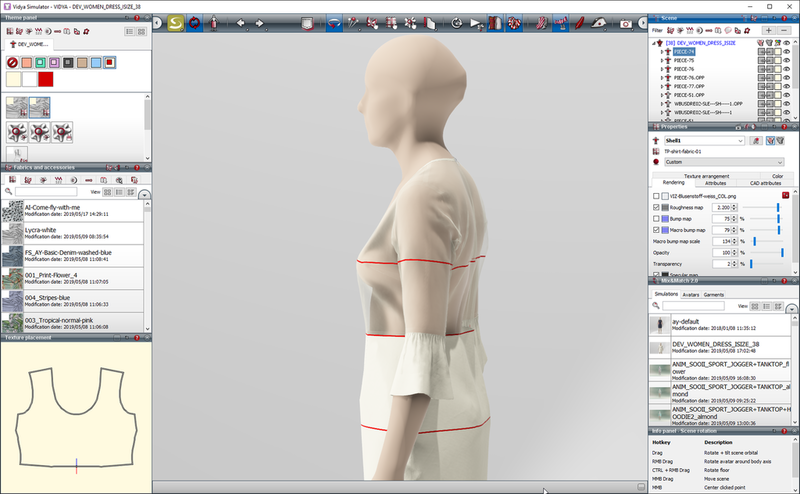

One example of a fit solution is the 3D Vidya product development tool from Germany’s Assyst, part of the Human Solutions group, that provides 3D visualisation of garments in real time. The software uses data from the international body dimension portal iSize, which offers access to information from 100,000 participants in ten countries.

"iSize helps you to define your target groups and to make sure you have the perfect fit right from the start," says Dr Andreas Seidl, CEO of Assyst. Customers have told Assyst they can develop products more than 50% faster, "because they do not produce any wrong samples any more."

Also seeing an increase in demand for 3D fit tools is Alvanon, whose Alvanon Body Platform (ABP) is a cloud database designed to provide a fast and accurate way for brands and retailers to share their 3D fit and core body standards across the supply chain.

The platform uses Alvanon’s virtual AlvaForm – a digital representation of the company’s AlvaForm dress and body forms – to create 3D fit standards and realistic virtual prototypes.

Assyst’s 3D Vidya product development tool

Jason Wang, chief operating officer at Alvanon, says that since launching last year, more than 160 brands have uploaded their 3D fit standards to the ABP. “Our 3D virtual bodies allow brands and retailers to monitor fit and sizing within the digital supply chain.”

One brand using the platform is US sportswear label Under Armour, which last year went a step further by working with Alvanon to digitise its size range and create a 3D avatar fleet, from infant size 0 to Men’s 5XL. Wang says this is allowing it to make products with improved sizing and standardisation and “next-level accuracy.”

Also in this area is BodyBlock, from US-based Fit3D. Its database of 3D body scans allows the user to optimise grade rules, size constructs, and develop a library of 3D body models to integrate with computer aided design (CAD) tools. According to the company, users can perform a full sizing optimisation backed by validated data “in weeks, not months.”

Meanwhile, Lectra’s well-established solutions include Modaris, a 3D virtual prototyping module designed to be used alongside its Quick Estimate cloud application, which allows pattern development teams to make their own fabric estimates “on the go.”

Design process

The design process itself can reap immediate benefits from the use of 3D technology. One solution is Gerber Technology’s AccuMark 3D, which according to Ketty Pillet, the company’s vice president of marketing, can save users up to 75% in lead time “and reduce physical samples to one.”

Also in this space is EFI Optitex, whose solutions include its Pattern Design Software (PDS), which combines 2D design with 3D visualisation. PDS 2D, which creates digital patterns, is complemented by PDS 3D so that the user can visualise true-to-life virtual samples. Amit Ben-Sheffer, head of product at EFI Optitex, says it can “create accurate simulation, tension maps for fitting, photorealistic rendering, colourways and print placement, and as an avatar editor.”

Enhanced connectivity

Workflow is another key area. Centric Software has developed an integrated digital 3D design and development process which Ron Watson, VP product at Centric Software, explains is “both natively integrated so as to give users more control and flexibility from within Centric PLM, and also software-agnostic, encompassing several 3D fashion solutions, such as CLO, Browzwear and EFI Optitex.”

Among other things, the new 3D innovations feature Centric’s 3D Connect, a collaborative design and product development tool that enables 3D designers and product developers to work in their native 3D CAD environment while connected to product information in Centric PLM. Watson says Centric 3D Connect is designed to allow brands “to iterate more product designs faster and earlier in the ideation and development process.”

Centric 3D Connect integrates PLM and multiple 3D tools

Developing 3D workflows

PixelPool also aims to help the fashion industry develop 3D workflows. Its services range from consulting clients on setting up internal production processes and how to approach change management, to the complete outsourcing of the 3D production process to PixelPool’s asset production teams. Its Dtail software platform makes full use of 3D assets once they have been produced.

“Clients that do not yet have an internal asset production pipeline can use Dtail’s generic 3D library to get started,” Joost Alferdinck, chief product officer at PixelPool, explains. The platform helps companies set up virtual sample production, for instance.

Meanwhile, Bamboo Rose provides a tool-agnostic 3D smart connector that allows clients to leverage the 3D tools of their choice and integrate those 3D files with the Bamboo Rose platform.

“Clients can take a 3D file, drop it into the Bamboo Rose platform, and automate the creation of a tech pack based on the file's data,” says Nate Fleming, the company’s director of marketing. “This allows retail clients to accelerate the design process, reduce risk of administrative errors, and cut down on physical sampling through digital collaboration on 3D files.” He adds that clients are specifically leveraging Browzwear and Vizoo file types with the Bamboo Rose 3D connector.

Another option is ‘Made for You,’ an end-to-end integrated web-based software solution from DeSL. According to the company, it provides a full suite of specialised modules “aligned with today’s digital transformation business strategy,” including PLM (product lifecycle management) and colour lifecycle management tools.

Headline image: Under Armour has worked with Alvanon to create a 3D avatar fleet

BACK TO TOP