A key challenge for designers is to think and design in virtual 3D from the very start of their process, while becoming familiar with the technical implications and requirements for their 3D models if they may be applied further downstream in the organisation.

“In a sense, the designer of the future has to be a concept artist, pattern maker and 3D artist combined,” says Joost Alferdinck, chief product officer at PixelPool.

Catherine Cole, CEO of Motif, a knowledge hub and e-learning platform launched by Alvanon in 2018, stresses that in order to successfully adopt 3D technology, clothing brands and manufacturers should first take a step back and “focus on the ‘why’ of digital transformation.”

She explains that “understanding what 3D solves positions companies to start thinking more strategically about 3D virtual design, fit and prototyping. It then becomes easier to identify the areas of opportunity and the teams that will pilot specific proof of concept projects.”

Cole says the key skills and experience needed include understanding digital work process flows, 3D computer aided design (CAD), analytical problem solving and an understanding of lean manufacturing. Given the challenge of upskilling staff while still managing business-as-usual, she advises that companies carry out skills training on a small scale, as this “will enable you to deliver measurable results quicker and facilitate training.”

Implementation plan

Amit Ben-Sheffer, head of product at EFI Optitex, adds that brands should “build a detailed implementation plan to help you achieve your goals. Map out each benefit, for example, and see how it affects a particular department, such as design. Once you’ve shown them the real value of 3D, begin expanding to other departments. Once employees are properly trained, they can help other employees during their 3D onboarding process.”

“Once employees are properly trained, they can help other employees during their 3D onboarding process”- Amit Ben-Sheffer, EFI Optitex

Savannah Crawford, chief collaborator at fashion technology company Tukatech, says another option is for a 3D sample maker to work with a digital pattern maker, “similar to the way pattern makers and sample makers worked together when everything was in-house.”

She explains that the 3D sample maker should be focused on becoming proficient at 3D design and fit, rather than adding 3D to the workload of pattern makers or technical designers. She says this means the technology either reduces the staff headcount “or makes the same staff more productive.”

Reaping the rewards

Ron Watson, VP product at Centric Software, notes that Centric PLM offers new “3D visualisation enhancements that can be used with or without a connection to a 3D CAD solution, even for users not specifically trained in the art of 3D development.”

Watson adds that it is not just the design and product development teams that reap the rewards from transitioning to 3D design. “Photorealistic 3D models can be shared with suppliers before production; especially useful when creating personalised products. This cuts the cost and time associated with sampling and ultimately speeds time to market for improved market responsiveness.”

“Photorealistic 3D models can be shared with suppliers before production; especially useful when creating personalised products” - Ron Watson, Centric Software

Another consideration is how much work can be reshored and to what extent it can be undertaken at outsourcing locations overseas. Cole says that because the Alvanon Body Platform provides the ability to approve fit and grading across a whole size range at one time, eliminating the need for physical size set samples, it has “led the way to more accountability being managed by offshore or regional teams.”

Crawford adds that with Tukatech’s TUKAcloud web-based system offering a central hub for 3D samples and all related files, “the configuration of work is flexible between teams, even if they are on different continents.”

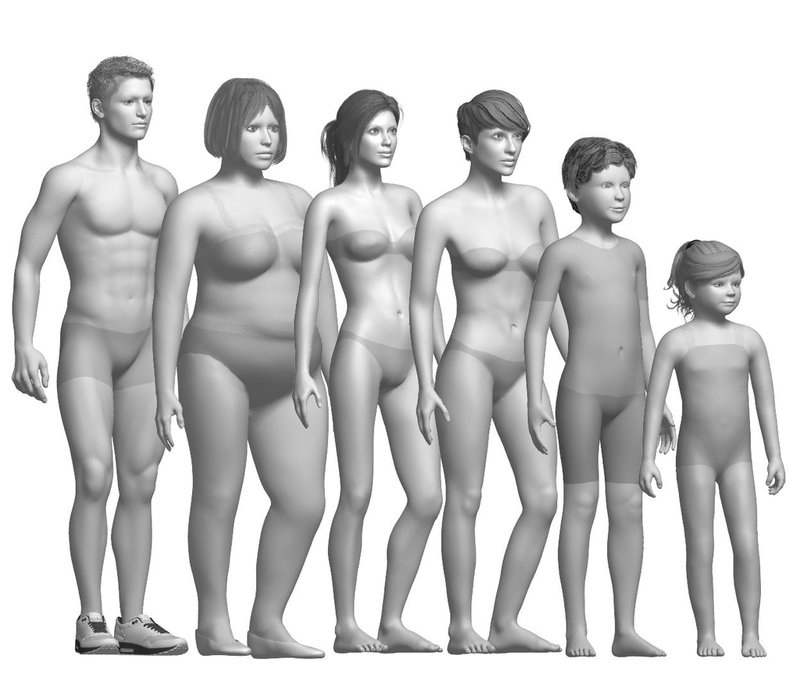

Tukatech's TUKA3D virtual fit models

Training for the future

Looking further ahead, training of the next generation of industry professionals is also vital. “The most important aspect of bridging the talent gap is in partnering with fashion colleges and university programmes,” according to Crawford. She says students need to either learn how to create 3D samples, or become familiar with analysing 3D samples. “In either case, they are ready to add value upon graduation, and will not require the same shift in mindset required of those who have been in the industry for years.”

PixelPool’s Alferdinck notes that graduates are now more able to embrace the changing role of the designer, as “more and more fashion design schools are including 3D design as a part of their curriculum.”

However, Dr Simeon Gill, senior lecturer in fashion technology at the University of Manchester, warns that when it comes to using virtual fit systems, brands need to be wary if new entrants do not have the long experience in physical fit systems that would help guide their decision-making. He says there could be a danger that a graduate using 3D fit technology is “going to be making judgements based on perception that’s not grounded in reality.”

Headline image: 3D digital sample from EFI Optitex

BACK TO TOP