insight

The rise of the 3D body scanner

More than two decades have passed since the first 3D body scanners were developed for the apparel industry, but technologists and designers continue to find new ways to hone the systems in response to rising demand among brands and manufacturers for direct-to-consumer sales following the pandemic. Kathryn Wortley investigates.

Increasingly tech-savvy consumers, an uptick in e-commerce and appeals for more sustainably sourced and produced apparel point to growth in the adoption of 3D body scanners, prompting vendors to keep innovating.

Evolving technology

Body scanning is one of the core 3D technologies that is radically transforming the fashion industry, according to Alexandra K Mann, media relations manager at the Fashion Institute of Technology, New York.

“Having access to accurate representations of a person’s size and shape enables a degree of personalisation that was previously unavailable to the broader consumer,” she says. She stresess how apparel can increasingly be designed, customised, fitted, tested and revised using new digital workflows that are built around 3D fashion design software.

With such evolving systems at their fingertips, designers are gaining more freedom “to try out ideas that are customised for individual differences” and ensure that “designs fit well and look good on a wide range of sizes and shapes.”

Custom-made garments are the fastest growing sector within the industry.

The pursuit of looking good is driving change in apparel. Custom-made garments are the fastest growing sector within the industry, according to John Fijen, managing director of US-based 3D scanning specialist [TC]² Labs.

In the past 18 months, the North Carolina-based company, which offers a full suite of 3D body scanning services, from training and consultancy to installation and maintenance, has made a lot of progress in technology, according to Fijen. This includes extensive improvements in [TC]2’s TC2-19M and TC2-19 tablet.

The company argues the former has “best-in-class” accuracy, being able to scan subjects in one second and processing data in eight seconds or less, including creating an avatar, extracting measurements and saving files.

Using 3D body scanning to facilitate a better online shopping experience is likely to increase as the Covid-19 pandemic continues to curb traffic to brick-and-mortar apparel shops and drive consumers online for fashion purchases.

Digital growth

Interest in digital systems has grown over the past year and provision of the equipment by brands has accelerated due to the global health crisis.

“The pandemic has decreased people’s physical contact, which hinders the custom apparel business, and driven the return of huge volumes of e-commerce purchases due to consumers’ lack of understanding of brand sizing and fitting,” explains Rick Yu, co-founder and CMO of TG3D Studio.

In response, the Hong Kong-based 3D technology company developed a mobile 3D body scanning feature based on its existing body service. This allows customers to be scanned at home and gives retailers “access to hundreds of body measurements that provide more personalised product recommendations and services,” he points out.

Covid-19 has also reduced opportunities to carry out maintenance, so TG3D Studio has enhanced its accuracy detection algorithm to make its physical body scanners more robust against any possible type of environment and user behaviour. The company’s efforts are paying off.

In 2020, the tech was used by Weekday, a member of the Hennes & Mauritz group (H&M), to create Body Scan Jeans, on-demand apparel that promises custom-made jeans in 30 minutes. After the scanning and translation of data into an avatar and measurements, users can customise their jeans’ fit, waist, leg, length, wash, thread colour and trims.

Yu believes the 3D avatar result from a 360˚ body scanner will always spark intrigue with likes, shares and comments on social media.

In November 2019, fitting systems middleware specialist Fit:Match introduced TG3D Studio’s technology to improve its customer experience. It also wanted to increase revenue at its brick-and-mortar pop-up store near Chicago. The company found the novelty of the process attracted more visitors, including a younger clientele.

Yu believes the 3D avatar result from a 360˚ body scanner will always spark intrigue with likes, shares and comments on social media.

“The virtual try-on service allows customers to try on different clothes digitally with their personal avatar scanned by the 3D body scanner, which makes it attractive for sharing on social media,” he explains.

Future possibilities

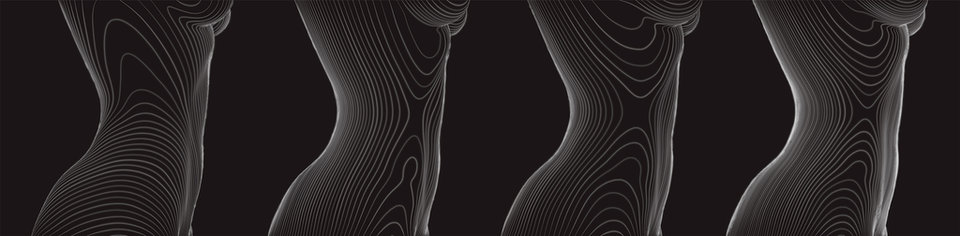

Ongoing developments in technology mean avatars can be used more frequently: “3D body scanning personalises the avatars, taking them from generic mannequins to realistic forms that designers can drape, style, colour-block, size and use to experiment with different materials - all before a single physical sample is made,” says Mann.

This progress has implications for not only workflow and industry systems but also for the environment.

Measurement data can be used to better understand the typical body shape of a target audience so manufacturers or brands can “make an informed buying plan and forecast according to geographical regions and size,” Yu continues. This information can avoid overproduction and overstocking, which could release strain on the warehousing and distribution processes in the apparel industry.

With such considerations, coupled with companies’ increasing drive to reduce margins while meeting customers’ expectations on quality and sustainability, 3D body scanning in apparel is likely to grow in popularity – not just because of the personalised fit, but also due to its environmental benefits.

BACK TO TOP