The fashion industry accounts for around 20% of wastewater and 10% of carbon emissions globally.[1] Clothes account for half a million tons of non-biodegradable microfibers reaching the oceans every year; the equivalent of more than 50 billion plastic bottles.[2]

It therefore comes as no surprise that Carry Somers, founder of Fashion Revolution, recently said “Environmental degradation […] remain rife within the fashion industry, and positive change is more urgently needed than ever to tackle climate change.”[3]

In recent years, the industry has tried to reduce its impact on the environment with brands like Burberry, Gap, H&M and Inditex pledging to reduce 30% greenhouse gas emissions by 2030.[4]

Innovative solutions are also being introduced such as - Allbirds’s shoes made from eucalyptus plants, H&M’s Conscious Collection leather jacket and cowboy shoes using Piñatex: a leather-like material made from the leaves normally discarded in the production of pineapples.[5]

More recently, at the May 2019 Copenhagen Fashion Summit, Google introduced a tool that uses data analytics and machine learning on Google Cloud to help brands estimate the environmental impact of particular items of clothing at the sourcing and design stages and use this data to help companies take action.[6]

Although the above is promising, “the pace of improvement is slowing down, while the industry as a whole is growing between 4% and 5% every year”[7]. This makes us question: Can these innovations actually be applied to every retailer? How complex are they to implement? What budgets are required? How quickly will we see benefits?

Whilst the answers are still unclear, there is a solution requiring minimal changes with big results: labels and packaging.

“How a product is labelled and packaged not only communicates its cost or information such as where it was made but also the quality and value of the product and potentially the story behind the brand.”

Often disregarded and left until the last-minute, labels and packaging are actually crucial. How a product is labelled and packaged not only communicates its cost or information such as where it was made but also the quality and value of the product and potentially the story behind the brand. Brands like Ted Baker place significant value in creating high quality and interesting packaging to help achieve a positive first experience and consumer buy in to the brand. Furthermore, without a care label, your product cannot be sold. Labels are therefore not only crucial but required. Unfortunately, few brands have the know-how to design their labels and packaging in a way that not only works with the product they are trying to sell but is also manufactured efficiently. As a result, they often pay more than they need to and unknowingly waste raw material that often just ends up in land fill.

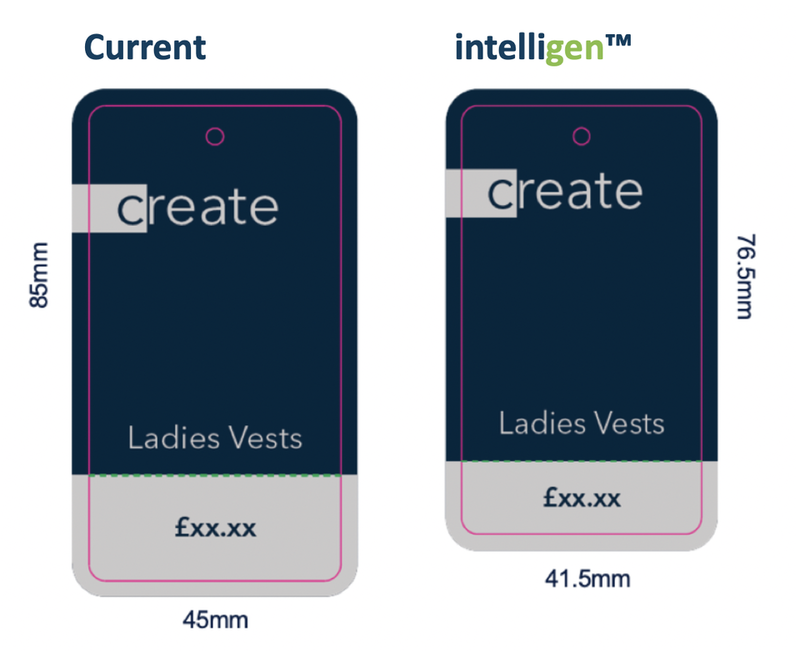

Product re-engineering solutions such as ITL’s Intelligen™ can remedy this. By making small changes to your label and packaging design, without compromising on performance, raw material utilisation is maximised and as a result not only do you reduce waste but also cost of production. Take this solution one step further and your label can be even more sustainable: by re-investing the savings made through reducing the cost of production into more environmentally friendly raw materials.

Brands such as Debenhams applied Intelligen™ product re-engineering to their Principles range:

“Without compromising the branding or the overall ‘look & feel’ of our Principles program, Intelligen™ provided a more cost-effective solution by maximising material usage and minimising waste & cost. We saved 5-10% on cost of production, reduced our paper consumption which therefore gave us a sustainability piece to highlight.”

Over the past years, the Fashion Industry has seen some great innovations introduced to reduce its impact on the environment. Despite these, retailers are still struggling to be more sustainable quickly and at a reasonable cost. Starting with the basics like labels and packaging can be a great start to your journey towards a more sustainable brand.

[3] https://www.vogue.co.uk/article/has-fashion-finally-got-sustainable-2019

[4] https://www.vogue.co.uk/article/has-fashion-finally-got-sustainable-2019

[5] https://www.vogue.co.uk/article/has-fashion-finally-got-sustainable-2019

Contact Information

ITL - Intelligent Label Solutions

Web: itl-group.com

Email: info@itl-group.com

Global contacts: itl-group.com/contacts-at-itl